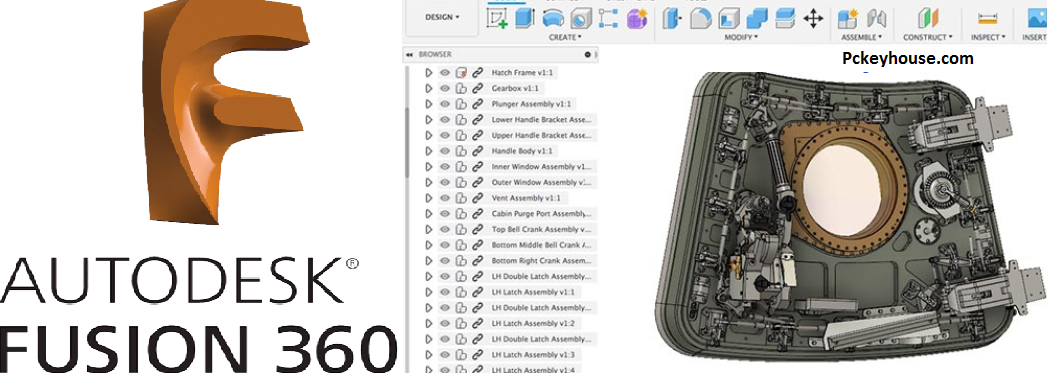

View shows assembly project which needs a dowel pin added, which passes. Also want to save any new components in the design as individual projects at the same time. Want to create and add newly created components to an existing design but need to have surrounding components present during the design of the new components. Want to know how to create 'External' assembly components in Fusion 360.

EXPLORE MORE.With Autodesk® Fusion 360, you can take advantage of the cloud features make project sharing and review easier than ever before regardless of where you are or your role in the design process. The Container House by STUDIODOT. Topology Optimized Brake Pedal - Generative Design Autodesk Fusion 360. OpenR/C Project - Frmula 1.

Yet, just this week I opened a model and somehow all references were lost. Top-Down DesignI’m going to pretend for a moment I haven’t spent 20+ years making sure my assemblies properly reference my parts. Now, let’s break these down and see how Fusion 360 approaches it differently. You know, in contrast to bottom-up modeling: Creating parts and adding them to an assembly. Here’s my definition of top-down design: Creating parts in context of an assembly. A smarty-pants, scholarly person on Wikipedia described top-down design as “breaking down of a system to gain insight into its compositional sub-systems in a reverse engineering fashion.” What-evs.

JointsOk, but what about Mates? After all, that’s what we started off talking about. The shock and joy to me in all of this? You start thinking, primarily, how features affect the entire design, not just the individual part. You create bodies, turn them into components, and edit everything as if it were one. Instead of moving in and out of parts, you work on the design as a whole. Here’s just a small example:What I’m getting here is that, this multi-body approach within Fusion 360 doesn’t interfere with your ability to model assemblies quickly. Joining a feature to an existing body and adding a new body (or component) is all done within the same command.

I struggled with this at first, but, wow, have Joints made assembly time more laid back.So, when you apply a Joints in Fusion 360, watch for the graphical feedback. Now, since Fusion 360 starts by assuming zero degrees of freedom, in most cases, only one Joint is required to define the relationship (or motion) between components. On the other hand, Joints define movement between two components. Let’s take a look at the difference.In every CAD application I’ve ever used, Mates remove degrees of freedom and, in most cases, require multiple mates applied to each part to properly position and restrict movement. (I promise that won’t be the last ‘joint’ joke.) Are Joints just another name for Mates? Well, yes and no.

It goes to the foundation of simplifying the product development process, starting with a top-down approach and working more efficiently with components. Joints and As-built Joints in particular save loads of time. In Fusion 360 however, As-Built Joints assume the component is already defined by the sketch, so all that’s left to do is to select the two components and determine the working behavior between the two by defining the type of motion.Hopefully you see why I saved the best assembly feature for second to last. Most CAD software doesn’t leave you with any other option but to do this. The context menu that appears under the cursor is handy to quickly select a different Joint Type once you use it a couple of times, and spend a little time getting to know which Joint to apply to which situation.If you want to show mechanical motion, what sense does it make to model parts exactly where they go in the final assembly, if you have to disassemble them, only to assemble them again? Yet, that’s how you do it to maintain the references.

You can work in context of the assembly across parts, you define movement between parts, and you build assemblies with less worry about references and a faster ability to choose versions. And yeah, of course you’re going to consider the structure of the assembly up front, but with Fusion 360’s approach to top-down design, you’re not constrained by working within one part or another. There are still some things I’m working through, like updating Joints after a geometry change, but maybe you have some tips for that. SummaryThese are the assembly features in Fusion 360 that are making me think differently about the design process. The references will automatically be updated. Pita’s file that was working previously.Not sure exactly when they added this, it hasn’t always been in Fusion 360, but sometime last year (June going by this feature overview) they added the ability to work collaboratively through Distributed Design with the option to Choose Version for a part that is already being used in your assembly.On top of this, since the Fusion 360 data lives in the cloud, independent of file locations, and a team would be working from the same data, renaming files doesn’t cause issues in Fusion 360.

And if you haven’t yet, you can try Fusion 360 here. If there are other assembly features I may have missed that have saved you time, definitely point them out.

0 kommentar(er)

0 kommentar(er)